“What is the ROI and payback time of a robot?”… It’s a common question when trying to decide if you should invest in a robotic solution.

The Return on Investment (ROI) is a crucial calculation when you are looking to add robots to your process. If the ROI is large and the payback time is short, it becomes much easier to justify investing in a robot.

But the ROI for a robotic system isn’t a fixed number. You can make decisions that will maximize the ROI and reduce the payback time.

Here are 9 tips to maximize your robot ROI:

1. Focus on Automating Non-Value-Added Tasks

We often concentrate on those tasks that add value to our products and services. However, high-value tasks are not always the most lucrative candidates for robotic automation, especially in the early stages of automating your business.

With robots, some of the biggest returns can come when you use them for non-value-added tasks. For example, adding a robot to pick, package, or transport products might seem like a small win. But automating such tasks can add up to significant savings as they allow you to move manual labor to more value-added tasks.

2. Choose Scalable Robotic Technology

In the past, industrial robots were often used in a similar way to conventional, fixed automation — the robot would operate in exactly the same way for its entire lifetime.

More recently, manufacturers have realized that robots are most valuable when they are agile and scalable. When you use robots in an agile way, you can easily scale them to meet changing production needs, which helps maximize their ROI. Remember… adaptable robots don’t become obsolete.

3. Adopt Dynamic Over Static Automation

Dynamic automation refers to a robotic system that changes in real-time to suit the changing needs of the production.

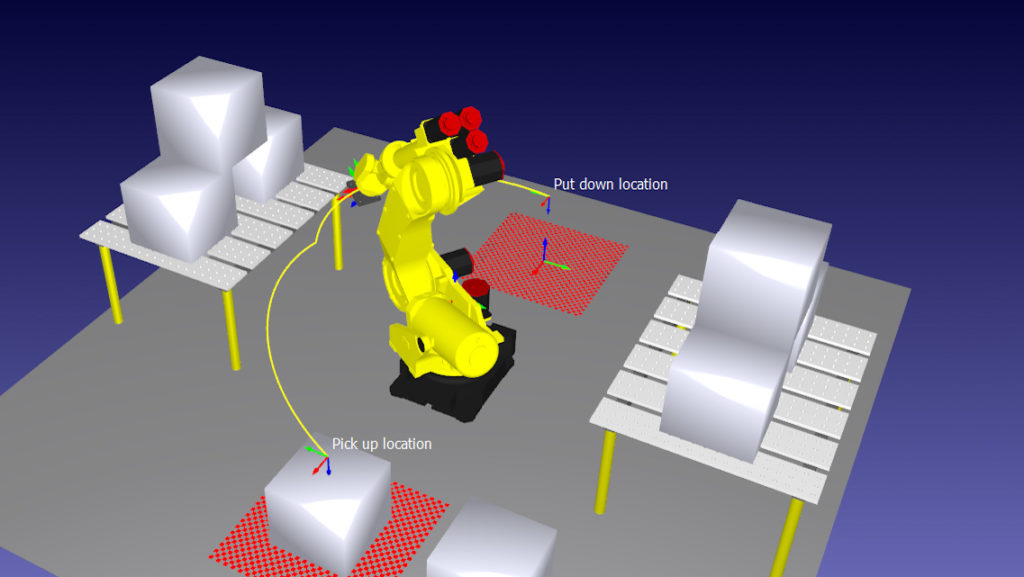

One way to make your robot more adaptable is to use a programming software like RoboDK. Our powerful offline programming and simulation tool allows you to create robot programs you can easily update to respond to your changing needs. You can also use RoboDK as part of a real-time monitoring system, allowing you to make quick adjustments to your robot.

4. Test in Simulation First

The more time your robot is operating in a real production environment, the sooner it will earn an ROI.

Simulation is a reliable way to reduce downtime with your robot deployment. It allows you to test and program your robot in a controlled virtual environment before you send your program to the physical robot itself. This reduces the trial-and-error traditionally associated with robot deployments and maximizes the time the robot is earning its return.

5. Optimize Your Robot Programs with Offline Programming

In the early days of a robot deployment, you will probably notice aspects of the robot’s operation that you can improve. These slight changes — such as reducing cycle time can contribute to a higher ROI over time.

With offline programming, you can change the robot’s operation while minimizing the downtime caused by online robot programming.

6. Reduce and Remove Unnecessary Movements

When you use a robot efficiently, you will get the most return on your investment. Another way to put this is… every unnecessary action or movement that the robot makes is losing you money.

For this reason, it makes sense to spend some time optimizing the paths that your robot moves through its workspace. Using a tool like RoboDK’s automatic task planner can help to ensure that your robot moves in the most efficient way possible.

7. Reallocate Labor for Greater Value

The idea of using robots to save labor costs can be a contentious issue. After all, some people are afraid they will lose their jobs to robots.

In reality, this fear usually misunderstands the purpose of robots and their true impact on jobs. Adding a robot means you can reallocate human labor to more valuable tasks, which improves the ROI of the robot. By automating the repetitive, routine processes, your skilled workers can focus on those tasks that use the most of their expertise.

A useful way to think about labor reallocation is this: If a task can be automated by a robot, giving this task to a human would reduce the job satisfaction and ROI of that employee.

8. Stabilize Processes by Reducing Variables

Getting the biggest ROI from your robot often involves gradually and systematically reducing the variables that reduce efficiency.

Examples of variables that you can reduce with robots include human error, delays, resource utilization, inconsistencies between work stations, compliance issues, and skill differences between human workers.

When you focus on optimizing such variables, you can create more standardized processes across your business. This makes it easier to scale processes and reduces waste, which all contributes to a higher robot ROI.

9. Prepare for Market Changes with Scalable Systems

When you optimize your robot system for scalability, you gain the advantage of being able to change production to adapt to market changes. This flexibility is key when you are looking to get the most from your robot investment.

Scalable robot systems affect robot ROI in various ways. For example, they allow you to prioritize modular design, helping to gain bulk cost discounts. Other impacts include simpler software updates, standardized predictive maintenance, and flexible deployment.

As you can see, maximizing the ROI of your robot is something that you have a lot of control over!

By deploying the robot using the right strategies, you can reduce the initial costs of deployment and continue to earn a return long into the future.

And RoboDK can be a core software tool to help you optimize your robot deployment.

Which of the tips listed seem most achievable to you? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel