Turntables are specialized devices for rotating objects during manufacturing. When added to a robotic setup, they can significantly improve your productivity.

Adding a turntable can help to improve the precision, control, and flexibility of many robotic applications. They can also improve the consistency of product handling and reduce manufacturing errors.

What types of turntables can you use with robotic manufacturing?

How can you add a turntable to your automated cell easily?

And how can you make turntable programming easy?

In this article, we look at what types of turntable are available and how you can easily add a turntable to your robotic setup.

What Turntables are Used For in Robot Manufacturing

Industrial turntables are rotating mechanical devices used to orient objects or materials. They are designed to move heavy objects with precision and can be powered manually, electrically, or hydraulically.

With robotic manufacturing, automated turntables can play a critical role in scaling production as they remove the need for a human to orient the workpiece.

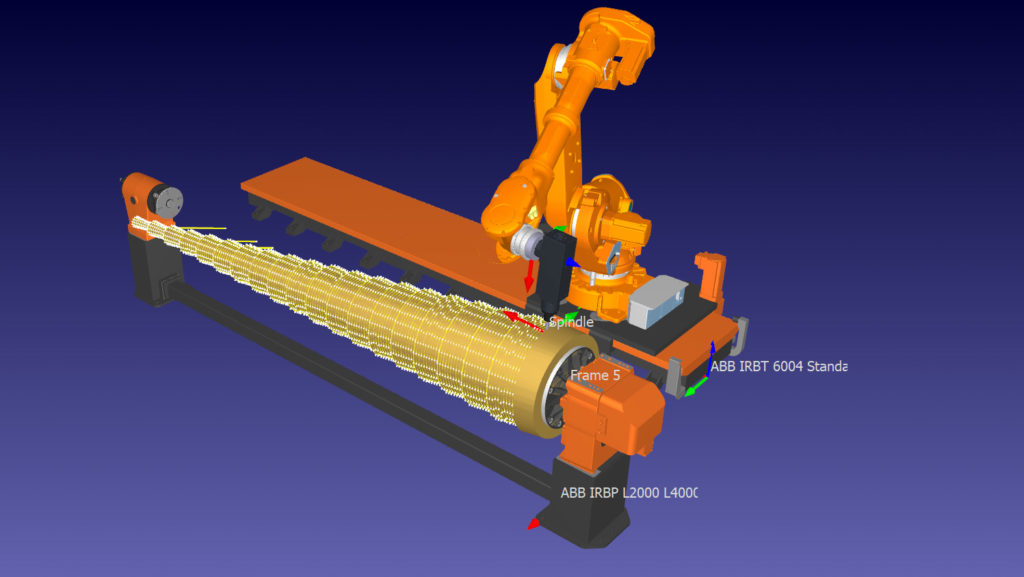

From one perspective, a rotating turntable simply acts as an additional axis to the robot. For example, combining a 6 Degree of Freedom (DoF) robotic manipulator with a single-axis turntable creates a 7 DoF system.

A few example applications for turntables in robotic manufacturing include:

- Assembly operations — A turntable can orient the workpiece to make certain assembly operations possible, without an operator having to manually reorient the piece.

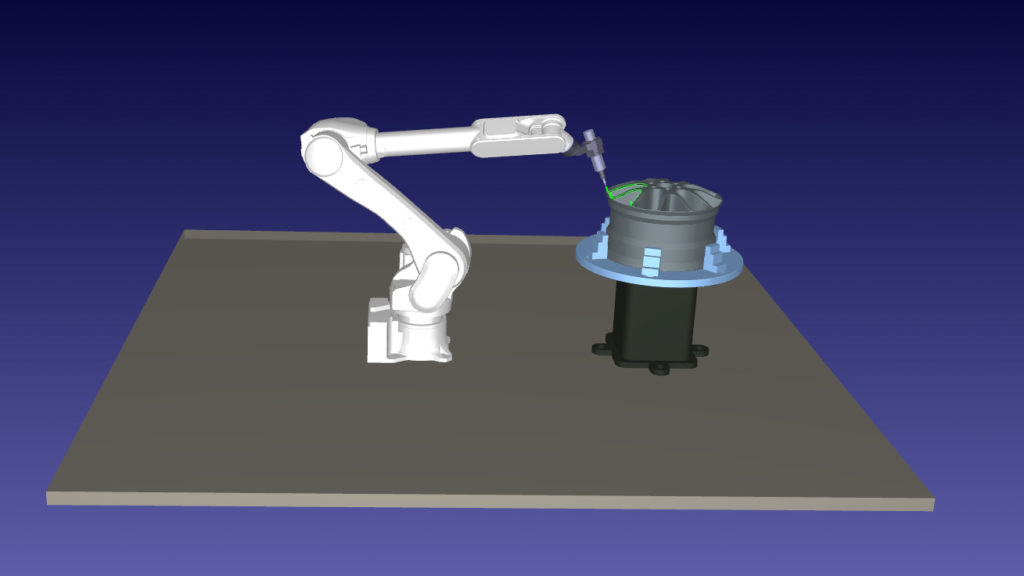

- Quality control and inspection — Orienting products at precise angles is a key step in many inspection processes. A turntable can achieve this easily.

- Finishing processes — Finishing tasks like painting or coating can be greatly improved by an accurate turntable, particularly one that supports continuous rotation.

Types of Turntables and Their Applications

Turntables are just one of several types of positioners for robotic applications. Others include multi-axis positioners, headstock and tailstock, and Ferris wheel positioners.

There are also various types of turntables that you might consider, depending on the needs of your application.

Indexing turntables are a common type of turntable used for precise positioning. They rotate at set increments. This makes them particularly useful for applications like inspection, which require parts to be presented with consistent orientations.

Continuous turntables allow for uninterrupted rotational movement. They are perfect for applications like robotic finishing and milling, which benefit from the smooth, continuous movement.

Elevating turntables add an extra vertical Degree of Freedom, allowing for height adjustments during operation. This makes them well suited to more complex robotic tasks and those that benefit from variable height, such as some packaging tasks.

Whatever type of turntable you need, the key to success is choosing a system that makes it easy to integrate the turntable into your robotic application.

10 Steps to Adding a Turntable to Your Robot Setup

With RoboDK, programming your robotic turntable is as simple as programming the robot itself.

Here are the 10 steps for adding a turntable:

- Access the RoboDK Library: The Robot Library includes models for both basic turntable mechanisms and external axes from various brands.

- Load a Turntable Model: Download your chosen model and load it into the simulation environment.

- Align the Center of Rotation: Use RoboDK’s measurement tools to ensure the turntable’s base frame correctly aligns with its center of rotation.

- Attach a New Reference Frame: Create a reference frame, if one doesn’t already exist, which defines the base of the turntable.

- Set Rotation Limits: Enter rotation limits and other properties for the turntable, especially for applications like welding, where cable entanglement could be a concern.

- Add a Part to the Turntable: Load the 3D model of your part into the workplace and align it to the turntable.

- Test the Turntable Rotation: Before you program the movements, this is a good moment to rotate the turntable manually in the simulator and make any necessary adjustments.

- Program Your Desired Positions: Create targets for the turntable’s rotation. Then, create a program that moves between these points using Joint Move commands, to avoid erratic behavior.

- Run the Simulation: Test your program in the simulator and keep making changes to improve its operation.

- Send to Your Physical System: Finally, when you have optimized the program, send it to the physical robot and turntable to test.

These steps are similar no matter what type of turntable you are using.

User Case Study: Enhancing Robotic Control with Python API

Questions around using turntables often come up in our RoboDK Forum.

One such case was from a RoboDK user David, who was looking to improve their turntable control with the RoboDK API.

David’s project required the robot to work in harmony with the turntable to ensure the tool maintained parallel orientation. The challenge was to manage the external axis without disrupting the tool’s trajectory.

Working with Albert at RoboDK, a solution emerged that involved creating a target to control the tool’s position, orientation, and joint axes. Albert explained how to maintain a constant pose of the robot while manipulating only the turntable joints.

This project shows how turntables can, at first, add complexity to a system. But you can mitigate this complexity by using the right tools in the right way.

What Will You Do With Your Turntable?

Adding a turntable to your robot cell can be an effective way to improve productivity and flexibility of your chosen task.

With the right programming environment, a turntable can be exactly what you need to optimize your robot application.

What tasks in your manufacturing workflow would benefit from a turntable?

If you have any questions about your integration, let us know in the RoboDK Forum.

What type of turntable is best suited to your task? Join the discussion on LinkedIn, Twitter, Facebook, Instagram, or in the RoboDK Forum.. Also, check out our extensive video collection and subscribe to the RoboDK YouTube Channel